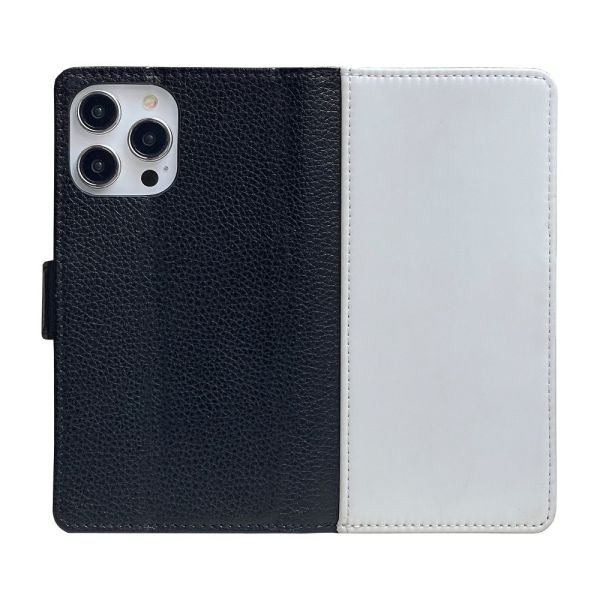

Printable sublimation PU leather flip wallet phone cases with a stand are protective phone accessories that combine functionality with customization options. Here’s a breakdown of what they are:

Key features of Printable Sublimation PU Leather Flip Wallet Phone Cases With Stand:

-

Material:

- Made from high-quality PU leather for durability and a premium look.

-

Sublimation Printable Surface:

- Designed for sublimation printing, allowing for vibrant, full-color designs that are long-lasting.

-

Wallet Design:

- Multiple card slots and a cash pocket for convenient storage of essentials.

-

Stand Functionality:

- Easily converts into a stand for hands-free viewing, ideal for watching videos or video calls.

-

Compatibility:

- Available for various phone models, ensuring a snug fit and easy access to buttons and ports.

-

Closure Mechanism:

- Features a secure magnetic or snap closure to keep the case closed when not in use.

-

Protection:

- Provides protection against scratches, bumps, and minor drops, helping to keep the phone safe.

-

Lightweight and Slim Design:

- Maintains a slim profile while offering functionality, making it easy to carry.

-

Customizable:

- Perfect for personalization, making it a great option for gifts or promotional items.

-

Easy Maintenance:

- Easy to clean and maintain, ensuring the case looks good over time.

These features make these cases a popular choice for those looking for functionality combined with personalization options.

Sublimation Printing Process:

Design Creation:Users create a custom design using graphic design software, ensuring it fits the dimensions of the case.

Printing:

The design is printed on sublimation transfer paper using dye-sublimation ink, which is specially formulated for this process.

Heat Transfer:

The printed transfer paper is placed on the cover and heated using a heat press. The heat activates the sublimation ink, turning it into gas that bonds with the material.

Final Product:

Once cooled, the design is permanently embedded in the cover, resulting in a durable and vibrant finish.

Benefits

Durability: The sublimated designs resist fading, scratching, and peeling, ensuring long-lasting quality.

Personalization: Ideal for creating unique, customized products for gifts, promotions, or personal use.

Functionality: Combines protection for the phone with the practicality of a wallet and the convenience of a stand.

Uses

Gifts: Perfect for personalized gifts for friends and family.

Promotional Items: Businesses can create branded covers for marketing purposes.

Personal Style: Users can express their individuality by customizing their phone cases with personal images and designs.

Summary:

A sublimation printing flip leather card wallet stand cover is a versatile accessory that offers protection, functionality, and personalization. It is an excellent choice for anyone looking to combine style with practicality in their phone accessories.

The sublimation printing process is a popular method for creating vibrant, long-lasting designs on various substrates, including fabrics, ceramics, and specially coated materials like phone cases. Here’s a detailed explanation of the process:

1. Design Creation

Software: Create your design using graphic design software (e.g., Adobe Illustrator, Photoshop, or specialized sublimation design software).

Resolution: Ensure the design is high-resolution to maintain quality after printing.

2. Printing

Sublimation Ink: Use dye-sublimation inks, which are specially formulated for the sublimation process.

Printer: Utilize a sublimation printer, which is equipped with specific dye-sublimation cartridges.

Transfer Paper: Print the design onto sublimation transfer paper using the printer. The ink is printed in reverse (mirrored) so that it appears correctly when transferred.

3. Preparation of Materials

Sublimation-Ready Substrate: Ensure the material (like a phone case, fabric, or mug) is coated with a polymer layer that allows for sublimation. Materials like polyester or specially coated items work best.

Cleaning: Clean the surface of the substrate to remove any dust or oils that could affect adhesion.

4. Heat Transfer

Heat Press: Place the printed transfer paper on the substrate and use a heat press to apply heat and pressure.

Temperature and Time: Set the heat press to the recommended temperature (usually between 350°F to 400°F or 175°C to 200°C) and time (typically 30 to 60 seconds, depending on the material).

Sublimation Process: As the temperature increases, the sublimation ink turns into gas and permeates the material. When it cools, the gas solidifies back into a solid state, creating a permanent bond with the substrate.

5. Cooling and Finishing

Remove Transfer Paper: Carefully peel off the transfer paper after the heat press cycle is complete. The design should now be embedded in the material.

Cooling: Allow the item to cool down before handling it to prevent smudging or distortion of the design.

6. Quality Check

Inspection: Check the final product for any imperfections or issues with the print quality.

Packaging: Prepare the sublimated items for sale or distribution.

Advantages of Sublimation Printing

Durability: The designs are embedded into the material, making them resistant to fading, scratching, and peeling.

Vibrant Colors: Sublimation allows for a wide color gamut, producing vivid and detailed images.

Versatility: Suitable for various materials and products, including textiles, ceramics, and custom merchandise.

Conclusion:

The sublimation printing process is a highly effective method for creating customized products with beautiful, durable designs. It’s widely used in various industries, from promotional products to fashion, due to its versatility and high-quality output.

What is sublimation coated phone cases?

Sublimation coated phone cases are specially designed cases that have a coating applied to them, allowing for the sublimation printing process. Here’s a breakdown of what this entails:

-

Sublimation Coating: The surface of the phone case is treated with a special polymer coating that allows sublimation inks to bond effectively. This coating is typically white and smooth, providing a perfect canvas for printing.

-

Vibrant Printing: The sublimation process involves transferring dye onto the coated surface using heat and pressure. This results in vibrant, high-quality images that are embedded into the material rather than just printed on top.

-

Durability of Designs: Since the dye is infused into the coating, the designs are resistant to fading, scratching, and peeling, ensuring that they remain intact over time.

-

Customizability: These cases can be easily personalized with images, logos, or patterns, making them popular for promotional items or custom gifts.

-

Material: Sublimation coated cases are often made from materials like Plastic(PC),Polycarbonate,Rubber(TPU),Aluminum, which are both durable and lightweight.

-

Variety of Styles: They come in various styles and sizes to fit different phone models, including slim and rugged designs.

In summary, sublimation coated phone cases are designed specifically for high-quality, durable printing, allowing for vibrant personalization that lasts.